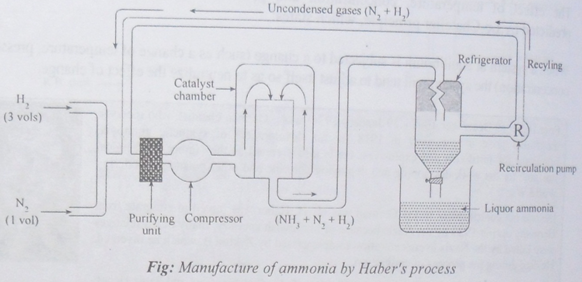

Theory:

NH3 is manufactured by Haber’s process. In this process, pure nitrogen and hydrogen gases react in the ratio of 1:3 by volume in 400°C-500°C temperature, 200-900 atm pressure in presence of iron as catalyst & molybdenum as promoter.

Fe/Mo (400-500°C)

N2+3H2 ——————–> 2NH3+ heat

(200-900atm)

Conditions for maximum yield:

1. Low temperature:

Since the reaction isexothermic, it favors low working temperature for maximum yield of product i.e. around 500°C.

2. High pressure:

Four volume reactant gives two volume of product i.e. volume is reduced to half. Hence, there is maximum production of ammonia at 200-900 atm pressure (high).

3. Use of catalyst:

Use of catalyst makes the reaction faster in forward direction. Hence, the catalyst like iron (Fe) & promoter like molybdenum (Mo) is used for maximum yield of the product.

4. Purity of reactant:

The purity of the reactants Hydrogen (H2) & Nitrogen (N2) helps in the more yielding of the product.

5. Concentration of reactants:

More the concentration of reactant, more the production. So, high concentration of hydrogen and nitrogen is used.

Top comments (0)